Soldering Guide for Industry

This Soldering Guide for Industry will provide information about solder, the forms that are availabe and the types and uses by industry.

All About Solder

Solder is a fusible metal alloy used to create a permanent bond between metal workpieces. In order to join metals, solder must be melted, so a suitable alloy for use as solder will have a lower melting point then the pieces it’s intended to join. Soft solder has a melting point range from 90℃ to 450℃ (190℉ to 840℉) depending on the metal alloy makeup.

Industries where is solder is commonly used includes electronics, plumbing, roofing, automotive, stained glass and jewelry. Solder-wire is available in a range of thickness for hand-soldering, it is also available as a paste or foil shaped. Plumbers often use bars of solder for electronic applications because they are thicker than wire. Jewelers often use solder in thin sheets, which they cut into snippets.

Request A Quote

To get a quote, please fill out the form below. You can also contact us at 844-564-6087 or via email at sales@mayeralloys.com.

"*" indicates required fields

Soldering Guide for Industry: Types of Solder

Lead-Based Solder

Tin-lead solder—commonly referred to as soft solder—is one of the most widely used soldering alloys across electronics, plumbing, and metalworking industries. This alloy is prized for its reliable melting characteristics, strong bonding performance, and ease of use.

One of the most important forms of tin-lead solder is the eutectic mixture, typically 63% tin and 37% lead (63Sn/37Pb). A eutectic alloy has a sharp melting point (183°C / 361°F), allowing it to transition cleanly from solid to liquid without passing through a pasty phase—ideal for precise and efficient soldering.

Tin-lead solder, also called soft solder, is commercially available with tin concentration. The greater the tin concentration, the greater the solder’s tensile and shear strengths. The addition of tin improves the wetting properties of the alloy, lead itself has poor wetting characteristics. Examples of tin-lead solder alloys are listed below. These solders come in a wide variety of diameters, as well as bars, ingots.

- 50Sn/50Pb

- 63Sn/37Pb

- 60Sn/40Pb

- 40Sn/60Pb

- 30Sn/70Pb

- 70Sn/30Pb

- 35Sn/65Pb

- 25Sn/75Pb

- 20Sn/80Pb

- 10Sn/90Pb.

Lead-Free Solder

As environmental and health regulations evolve, lead-free solder has become the preferred—and often required—alternative to traditional tin-lead alloys. Driven by the need to reduce lead exposure in the workplace and minimize environmental contamination, many industries have now made the switch to lead-free solder formulations.

Lead-free solder is a metal alloy designed to join metals without the use of toxic lead. These solders commonly contain combinations of the following elements. These elements are blended to deliver strong, reliable solder joints with reduced health risks and improved environmental safety.

Tin (Sn)

Copper (Cu)

Silver (Ag)

Bismuth (Bi)

Indium (In)

Zinc (Zn)

Antimony (Sb)

Most lead-free replacements for conventional 60Sn/40Pb have a melting point from 5 to 20℃ higher than their lead-based counterparts, though there are also solders with much lower melting points. Industries that typically use lead-free solder include plumbing and electronics. Lead-free solders are less hazardous to people and much more friendly to the environment where waste is concerned.

Rosin and Acid Core Solder

Rosin and acid solders are manufactured with the solder wire as a tube and the center of the tube contains the flux.

Rosin core solder contains a mild flux and is designed to solder parts where flux residue cannot be removed. It can be used in electric circuit boards or electrical connections. The residue from Rosin flux is non-corrosive which eliminates the need for post-solder cleaning. If you are joining wire or metals that operate under extreme conditions of temperature where fluctuations vary between cool to very hot, then most likely rosin core solder would be used. When using an electrical soldering iron for fine jobs, rosin core solder would suit the purpose, but you would need the thicker gauges where you are using blow torch methods.

Acid core solder is an aggressive type designed to solder steel to other metals. It is manufactured with a special type of chemical that helps for the solder of difficult types of metals. The acid core in the solder can be said to clean the oxidation off the metal, making for a satisfactory joint. Acid flux is used for metal mending and plumbing and rosin flux is used in electronics.

Soldering Guide for Industry: Forms of Solder

Solder comes in all different types of forms and shapes. Depending on what you need the solder for there are different forms in which you can have your metal delivered. A lot of this depends on what industry you are in, what metals you’re working with, and what type of project you’re working on. Some of the forms that are available include:

Anodes

Balls

Bars

Cakes

Cathodes

Cut Bars

Cut Cathodes

Foil

Flux

Granules

Ingots (regular & small)

Pellets

Pigs

Powder

Rod

Sheet

Shot (Polished, Unpolished)

Slabs

Waffle

Soldering Guide for Industry: Key Industries That Use Solder

Every industry in manufacturing, assembly and construction has standards of what metal alloys are commonly used. We have listed some of the major industries below that commonly use solder.

Plumbing

A plumbing system—no matter how expertly designed—cannot function safely or hygienically if inferior materials or components are used. The long-term durability of any plumbing system depends not only on the quality of its materials but also on the craftsmanship behind its installation. To ensure optimal performance, the materials used must resist external pressure, , especially when pipes are buried underground. It must also withstand environmental stressors, such as temperature fluctuations, corrosion, pH variations, and bacterial exposure. Finally, it must be able to handle mechanical strain from expansion, contraction, and vibration over time. Keeping all this in mind, some examples of lead-free solder alloys known for their strength, corrosion resistance and long term reliability for residential and commercial plumbing applications include 95Sn/5Sb (95% Tin / 5% Antimony and 97Sn/3Cu (97% Tin / 3% Copper). In addition to the lead-free options acid core solders are used for galvanized pipes in potable water systems and for general plumbing repairs. Using acid core solders are effective as they flow easily into the clean joints, allow molten metal to fully penetrate and the seal the connection, and create a durable leak free bond.

Radiator

Radiator solder can be similar to plumbing in that no matter how well designed your radiator, it will not hold up if you don’t use the right materials. Since different designs lead to differences in cooling ability, it is important to know what those differences are knowing the characteristic of metals in relation to your design concepts. You would need supplies to repair and assemble radiators, heaters and gas tanks. When trying to decide what metals to use, you have to look at the materials cost, the longevity or lifespan, and if repairing what the original radiator is made of, some examples of materials used in this industry include 15Sn/85Pb, 20Sn/80Pb, 30Sn/70Pb, 25Sn/65Pb and 40Sn/60Pb as well as aluminum and copper.

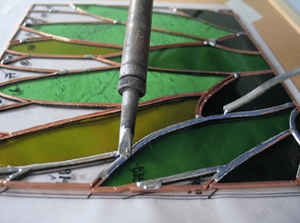

Stained Glass

When working with stained glass you need to make sure you are using high-quality solder because stained glass is a work of art. Solder is one of the essential tools when working with stained glass. It is used to join glasses to other glasses, ceramics, and metals. It is recommended in the stained glass industry to get 60Sn/40Pb but you can also use 50Sn/50Pb and 63Sn/37Pb depending on what you are working on.

The different types of solder used in stained glass soldering are:

50/50 solder is most commonly used inox and lamp assembly.

60/40 is most commonly used in lead and copper foil assembly.

63/37 is most commonly used for decorative soldering.

It is important to not use acid or rosin core solder for stained glass, only use solid-core solder. Materials used in the stained glass industry can also be used to create and restore stained glass windows, lamps, suncatchers, cabinets and doors. To use solder you must use a soldering iron that melts the solder to a liquid state (approximately 700 ℉). As well it is important to wrap each piece of glass in copper foil or lead came because the solder will not stick to glass alone.

Automotive

Jewelry and Figurines

Solder in jewelry making is a metal alloy of silver and copper or silver and zinc and is used to join two pieces of metal together. When creating jewelry and figurines you need to look for quality and wear when looking at metals to use. You have to look at what kind of jewelry you are making. The products produced in the industry are pewter figurines, earrings, necklace, bracelets, and games. Examples of these materials include Sn/Sb/Pb Alloys and lead-free, pewter alloys.

The two standard types of soldering used in the jewelry-making field are soft soldering and hard soldering. Soft solder is commonly used for stained glass styles. This is a low temperature melting solder and you use a soldering iron when working with it. Soft solder is easier to work with than hard solder but the bond that is created is not as strong as hard solder. Hard solder is commonly used to unite precious metals together. This is a high temperature melting solder and you need to use a torch when working with it.

If you are doing a complex piece it is best to work with hard solder then work your way down solders as needed.

To create a good blend of solder with the surrounding silver, work with the highest temperature solder possible. Low-temperature solder does not blend as well as high-temperature solder. Also, make sure to select your solder shape based on the job you are working on. Wire, paste and sheet solder are better for certain projects. Sheet solder can cover large areas and lays better on flat surfaces. Wire solder works better when working in smaller areas and when you need more precision.

Bait and Tackle

In the bait and tackle industry solder is used for many things including hooks, wire, bead, bladers, ball bearing, rings, loops, spacers, jigs, splits, sinkers and cannon balls. Typically materials include pure lead and antimonial lead alloys both are available in bar and wire form.

Wire Cloth

Medical

Medical equipment is becoming more and more advanced and new technologies are being created daily. Having advanced medical equipment is essential to making sure your medical practice is up to speed. New technologies and longer lifespans are driving the growing medical device and medical electronics manufacturing markets around the world.

Solder is commonly used in some of these products:

- The assembly of diagnostic and therapeutic catheters, micro-catheters and feed-through require precision solder products that are made to a tight tolerance and high-quality standards.

- In sensors, temperature-sensitive devices may need low melting alloys to prevent thermal stress during assembly.

- Soldering to some of the most widely used metals in the medical market, including Nitinol and stainless steel can be challenging. Removal of the tenacious surface metal oxides must be achieved before soldering can take place.

- In connector manufacturing maximum signal integrity is required to allow for the optimum flow of data and images.

- From diagnostic and imaging equipment to handheld monitoring devices, printed circuit boards are in almost all of the equipment used by doctors, hospitals and clinics.

- Lead is a dense and extremely versatile tool, making it the preferred material of high energy radiation operation. It is used in nuclear and radiology operations, including x-ray gamma ray and nuclear applications.

Some of the solder products frequently used in medical devices are solder paste, preforms, solder wire, solder spheres, and flux. Solder paste is a spherical, low-oxides powder available in various mesh sizes. Performs is a large die library of washers, squares, discs, frames, and special shapes.

How to Purchase Solder

When looking for the right solder for your project, you can refer to industry standards. There are many type of solder alloys, both lead-based and lead-free, as well as many form variations.To figure out what type of solder is best for your project, you can refer to this guide and our website. If you have a question or do not know, please contact us. Mayer provides FREE Technical Assistance. If we don’t carry what you need, we are happy to provide a referral for you.

Mayer Alloys offers a full line of the high quality, non-ferrous metals specializing in tin and lead-based alloys, and lead-free alloys for manufacturing and assembly. FREE Technical Assistance is always available to ensure you are getting the right materials for your project. Mayer can also help you with scrap reclamation for your solder and nonferrous metal scrap.

For more information, FREE Technical Assistance and current pricing, contact 844.564.6087, email sales@mayeralloys.com or fill out the form in the Request a Quote link below.

Get the Guide to Purchasing Solder

Solder Guide Form