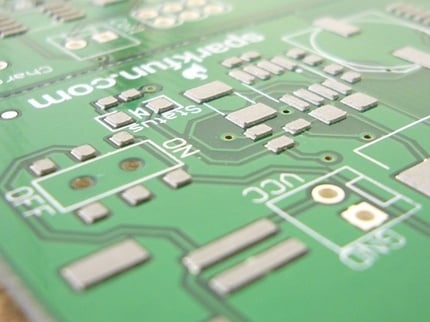

Solder paste is a material used in the manufacture of printed circuit boards to connect surface mount components to pads on the board. The solder paste is a mixture of solder spheres and a specialized form of flux. Flux is added to act as a temporary adhesive, holding the component until the soldering process melts the solder and fuses the parts together. Traditionally solder paste is a mixture of tin and lead but with recent legislation against lead, there has been a move toward lead-free solder paste.

There are a number of types of solder paste, but that use for electronic manufacture is a form that can effectively be printing onto the surface of electronic printed circuit board in the required place. The paste initially adheres components in place by being sticky, from there it is heated melting the paste. This forms a mechanical bond as well as an electrical connection.

There are a number of types of solder paste, but that use for electronic manufacture is a form that can effectively be printing onto the surface of electronic printed circuit board in the required place. The paste initially adheres components in place by being sticky, from there it is heated melting the paste. This forms a mechanical bond as well as an electrical connection.

When solder paste is used with care it enables very high quality soldered joints to be produced, very careful control is required to create this high quality solder joint. When working with solder paste it is necessary to apply the correct amount, and in the correct place. Too much paste may result in a short -circuit, too little may result in poor electrical connection or physical strength. Although solder paste typically contains 90% metals in solids by weight, the volume of the soldered joint is only about half that of the solder applied.

Solder paste must be refrigerated when transported and stored in an airtight container at a temperature 0 – 10℃ and then warmed to room temperature for use. Also always check the date on your solder paste because it can expire.

Mayer Alloys

Mayer Alloys is a solder distributor that stocks and supplies a complete line of solder. All material we stock and supply is guaranteed and certified to comply with ISO 9001 standards. Mayer Alloys stocks a full line of the highest quality, non-ferrous metals specializing in tin and lead-based alloys, and lead free alloys for manufacturing and/or fabrication. We will ship your items the same day it is ordered in most cases. Customer service and technical assistance is always available to ensure you are getting the right materials. For technical support, please contact us at 844-564-6087 or email us at sales@mayeralloys.com.